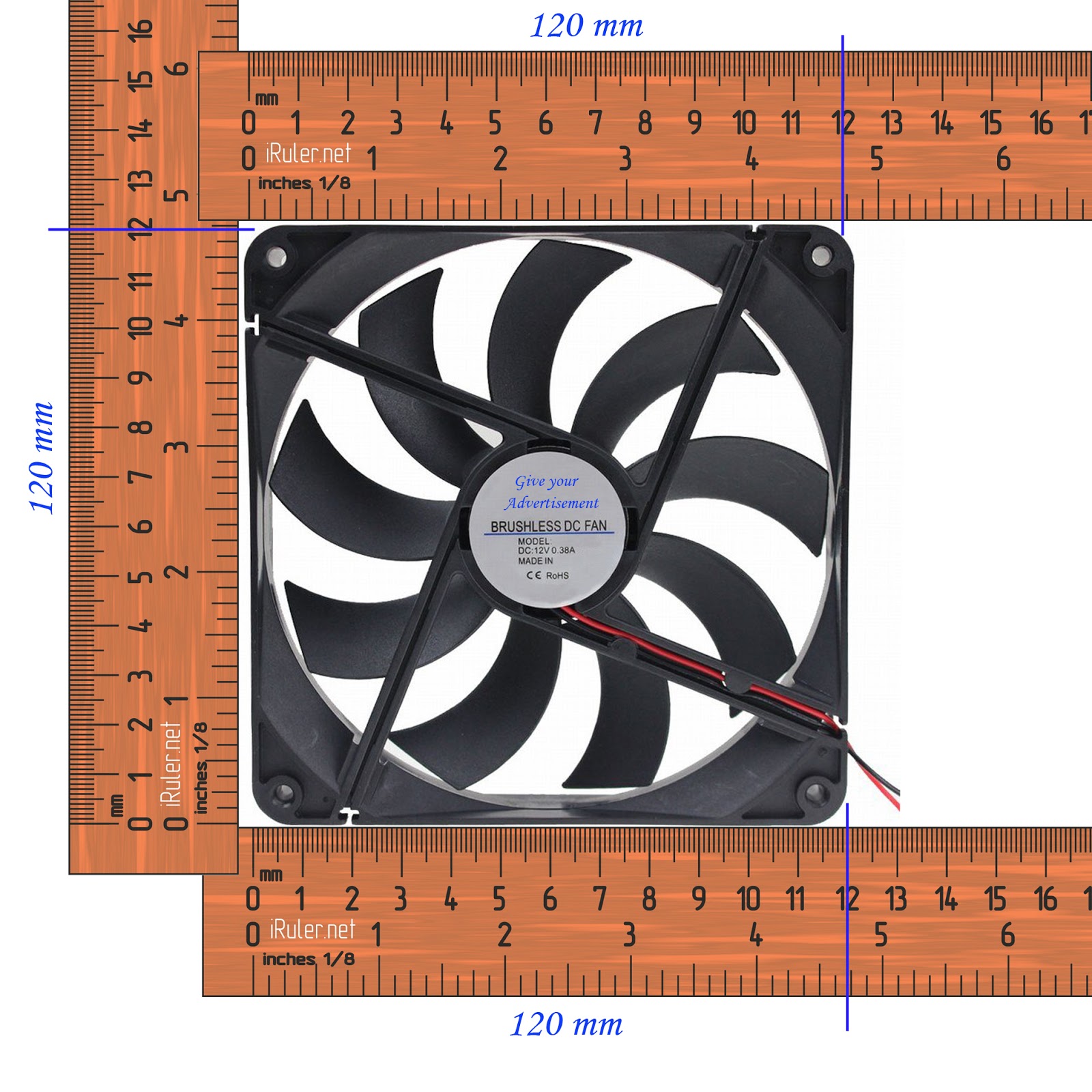

As case fans are often the most readily visible form of cooling on a PC, decorative fans are widely available and may be lit with LEDs, made of UV-reactive plastic, and/or covered with decorative grilles. Standard axial case fans are 40, 60, 80, 92, 120, 140, 200 and 220 mm in width and length. Some ATX tower cases have one or more additional vents and mounting points in the left side panel where one or more fans may be installed to blow cool air directly onto the motherboard components and expansion cards, which are among the largest heat sources. Case fans may be placed as intake fans, drawing cooler outside air in through the front or bottom of the chassis (where it may also be drawn over the internal hard drive racks), or exhaust fans, expelling warm air through the top or rear. The components inside the case cannot dissipate heat efficiently if the surrounding air is too hot. Applications įans are used to move air through the computer case. Chassis or case fans, usually one exhaust fan to expel heated air from the rear and optionally an intake fan to draw cooler air in through the front, became common with the arrival of the Pentium 4 in late 2000. Active cooling on CPUs started to appear on the Intel 80486, and by 1997 was standard on all desktop processors. In the IBM PC compatible market, the computer's power supply unit (PSU) almost always uses an exhaust fan to expel warm air from the PSU.

Standard pc fan sizes in inches manual#

A user can even supplement this function with additional cooling components or connect a manual fan controller with knobs that set fans to different speeds. A computer's BIOS can control the speed of the built-in fan system for the computer. Fan control is not always an automatic process. Fans attached to components are usually used in combination with a heat sink to increase the area of heated surface in contact with the air, thereby improving the efficiency of cooling. To cool these components, fans are used to move heated air away from the components and draw cooler air over them. If the filter you need is bigger than this, consider breaking it up into 2 or more smaller filters.While in earlier personal computers it was possible to cool most components using natural convection ( passive cooling), many modern components require more effective active cooling. Country to which the order will be shipped (this is to include a shipping quotation)ģx O/D 500mm x 168mm (I/D 470mm x 138mm) non-ferrous black frame/black mesh You can send us an email to request a quotation for your custom filter.Ħ.

Magnets will cling to ferrous materials (metals containing iron Fe) but not to non-ferrous materials (acrylics or aluminium). Write your email address, and which filter it is on the cutout, and send the cutout to the following address, or scan and email it to the address below.ĭetermine if the material where the filter should fit is ferrous or non-ferrous. You can then fit this cutout into the desired position and trim it until it fits exactly the way you want. If the filter is in a recess or has a shape that is hard to measure we suggest that you cut the shape out of stiff paper or board. < 2.5mm thick without the non-ferrous magnet and < than 3mm with the non-ferrous magnet included.įrame length Frame width 20mm-100mm 10mm 101mm-150mm 11mm 151mm - 180mm 12mm 180mm -200mm 13mm 201mm - 300mm 14mm above 300mm 15mm The reason for this increase in width is to ensure the structural integrity of the filter, but this is only a guide.ĭEMCiflex Filters have a low profile design. The width of the frame will increase as the size of the filter gets bigger as shown below. The minimum frame width on any filter is 10mm. Please note that the frame width has to be added twice (11mm for each side). The I/D will then be 98mm x 112mm.īelow is a guide to help you determine the appropriate frame width. in the image above, the vent size is 120mm x 134mm. If there are obstacles on the outside, like screws or protrusions, work with the O/D, so the outside of the filter fits the opening exactly.Į.g. Use the table below as a guide for the frame width to determine your I/D or O/D.

Measure the size of the vent that you need filtered. These will be either the inside dimensions (I/D), or outside dimensions (O/D), depending on your case. Please follow the instructions below to guide you in your design.

Here are a few pointers to keep in mind when designing your filter. You may order 1 filter if you so prefer and the cost of the filter will be in line with the rest of our filters. You may also choose the color of the frame and mesh from our colour range. We will accurately manufacture the filter to the measurements you give us. We can make any shape and size filters to your exact specifications. This is where you design the filter to suit your need.

0 kommentar(er)

0 kommentar(er)